Marek Mysliwiec:

“I am home at Tvilum.”

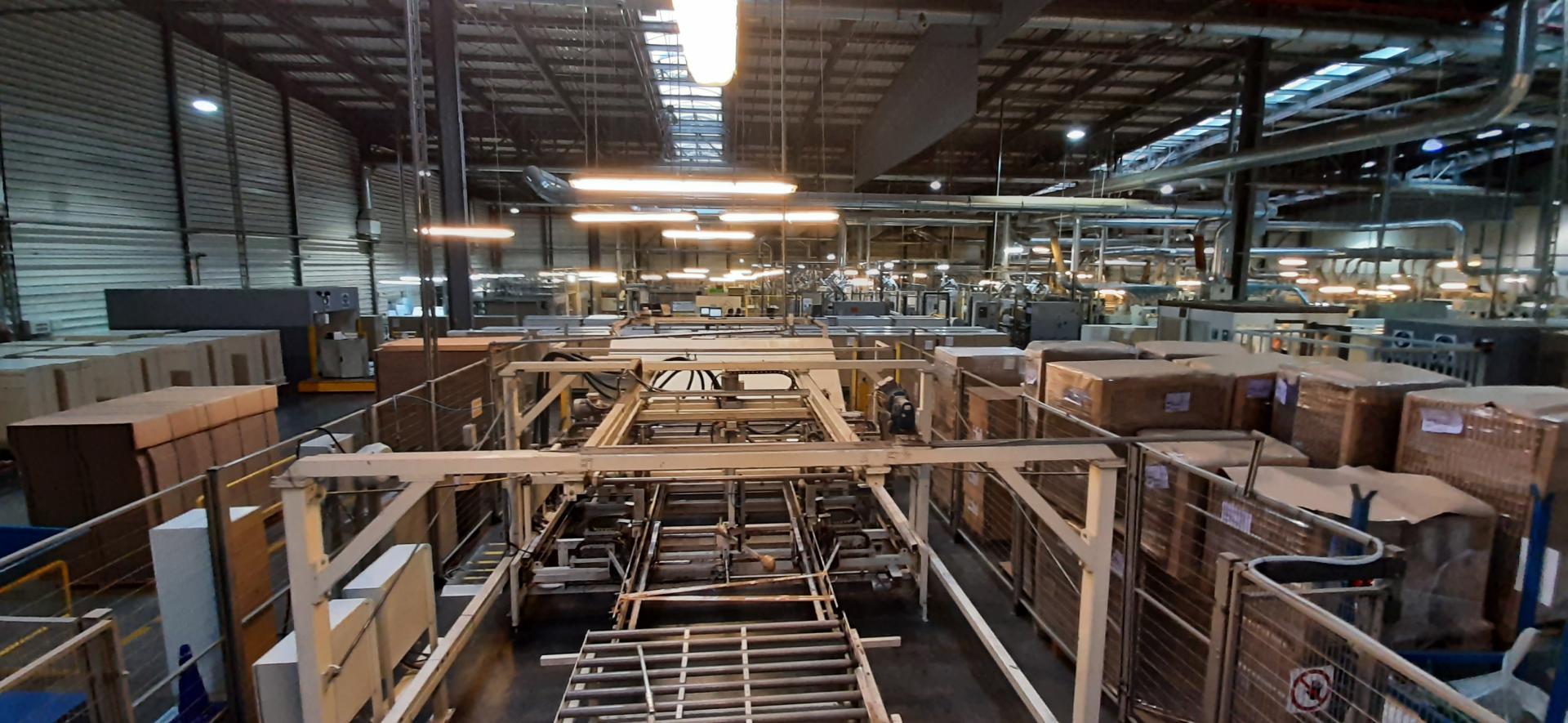

We started the development of what is today our factory in Szczecinek, Poland in 2016. What was initially a greenfield development – built on an empty 11 000 m2 lot – is today a thriving 18 000m2 factory complex employing over 140 people from the local community. One of the central people getting production up and running has been Marek Mysliwiec, Production Manager. On a sunny day in June, we sat down with Marek to discuss the past and present of our Szczecin factory and how it has become what it is today.

What is your history at Tvilum?

I have been working for Tvilum for 14 years. Before joining Tvilum I was working in Iceland as a CNC operator, but as time passed, I started to feel the call of home get stronger and stronger, so I decided to move back closer to home. I had a wife and children back in Poland, and I was only able to see them every three months, so that is what ultimately made me move back. Initially to Denmark in 2008, where I was initially employed via a temporary worker supplier but joined Tvilum full-time shortly after that.

How did you end up in Szczecinek and what was your first impression?

In 2016 I saw a notice on one of the boards at Fårvang where Tvilum was looking for people to work in Poland on starting up a factory. I applied and got the job. When I first arrived to Szczecinek in May of 2016 with Poul Lindberg, our country manager, this was just an empty lot with just one machine, which at the time was not even connected. So, we started building up the factory from the ground up. A large part of this was involved with building up the technical base, but we must not forget about processes and people, as those are even more important than machines. In doing this, we received big support from our 2 Tvilum colleagues in Denmark - Marcin and Jimi.

Talking about people – what is your method in getting the organization aligned towards a common goal?

It has been a process, but it is all about changing the mindset. My approach has been to lead the organization in focusing on production and the possibilities we have at our disposal. Having worked as an operator for many years, I understand how that approach has come to be, but my intention has always been to find an optimal way to operate the machines. I am focusing on KPI-s and raw figures, which are extremely important, and I also have chosen to focus on processes and getting the maximum out of the possibilities we have. What I focused primarily on, in addition to analyzing the current KPI's in order to achieve even better results, was a change in employees' awareness and development of the possibilities offered by machines, both technical and process.

Let´s talk about how your transition to your current role occurred – you are now de facto factory manager of Szczecinek?

When it became known that our then factory manager will be moving back to Denmark, I was offered to take on this responsibility. And I accepted. So, from 2021 onwards, I have been essentially acting as a factory manager here in Szczecinek, in addition to my duties as production manager. It was a big change for me, as in Denmark I had only been responsible for a specific segment in the process, but after becoming the overall responsible for the entire factory, my viewpoint had to change. I had to completely change my mindset.

How did Tvilum prepare you for this transition?

It all started with having a great mentor. Not having any formal training in management prior, I learned most of what I know today from manager Poul. There was a lot of trial and error but having this support from Poul’s side gave me the courage to test my ideas and approaches in real life scenarios. Tvilum also arranged some development process for Leaders what gave me new tools to even better manage and lead, but nothing prepares you better than learning by doing.

What are some of the recent projects you have been working on?

Environmental issues are top priority everywhere, Tvilum included, so we have spent a lot of time getting ourselves in compliance with ISO 50001 energy management system. But that is only one example – being a large organization, there is always something going on. Last year we produced 1.4M boxes of furniture, so even a minor improvement in efficiency or productivity has a big impact on the overall result. Also, improving safety is always a top priority, so there are always multiple initiatives ongoing in that area as well. We also started to extend our actions in Lean Manufacturing.

What is it like to work for Tvilum?

I will try to answer these questions with a short story. I am usually at the factory quite early in the morning, together with the morning shift, and when people in the next shift see me still at the factory, they sometimes ask me why I am not going home. My answer has always been: “I am at home”. I hope that answers the question. I have got that feeling because I have opportunity to do what I really like, and I am surrounded by fantastic Team.

Using the quote of John C. Maxwell “If You want to lead You need to grow. Good leaders are always good learners”.

It is easy to work for Tvilum because I appreciate working with Danish culture, management style and Tvilum values. It is very important to treat others with respect, deliver a supporting environment and let people grow.